CNC Alignment

Want faster setups? Better tool life? Repeatable cost savings?

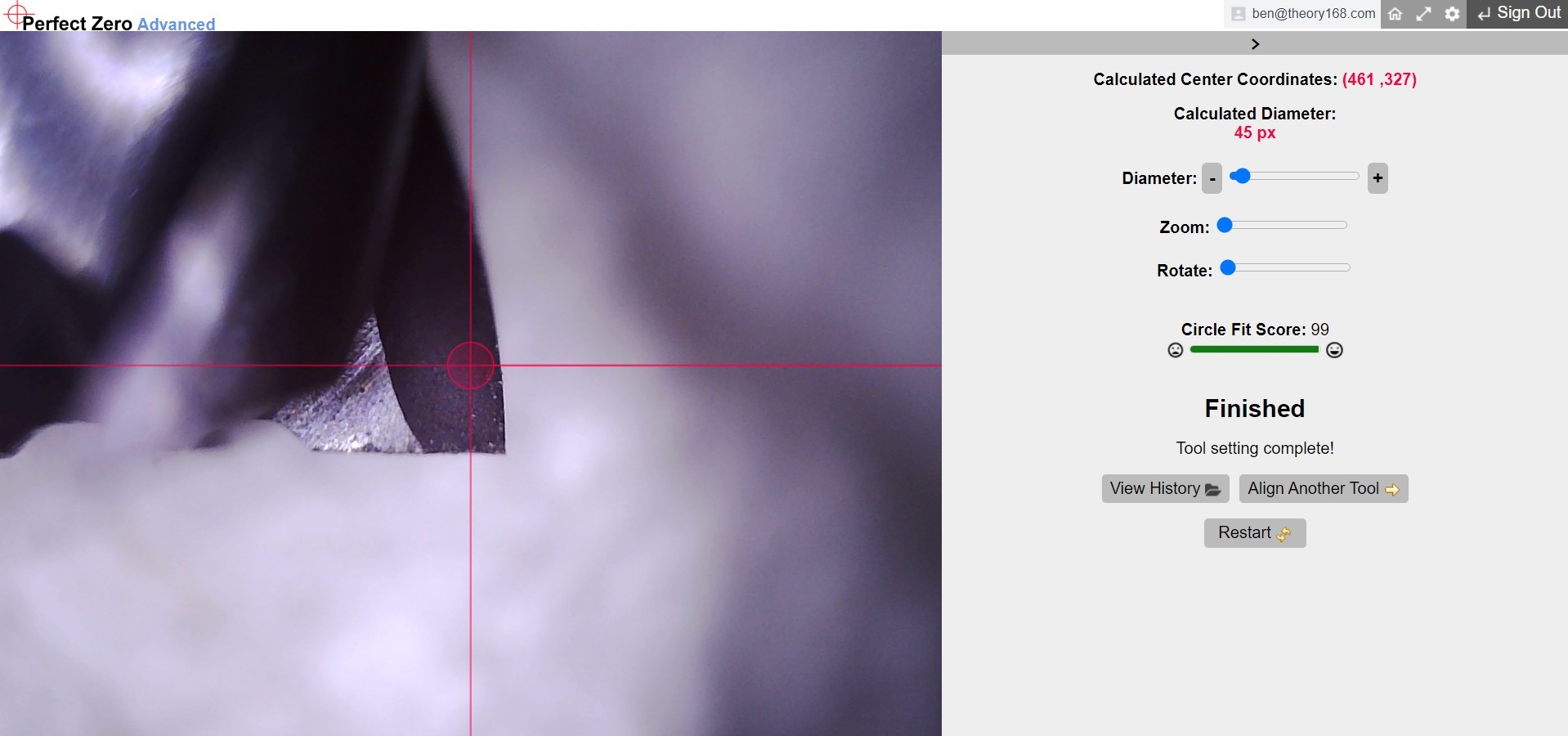

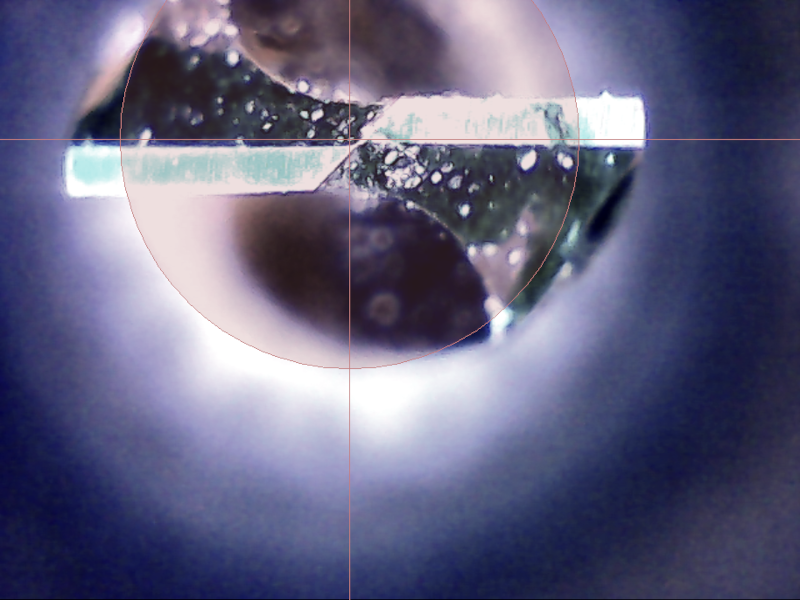

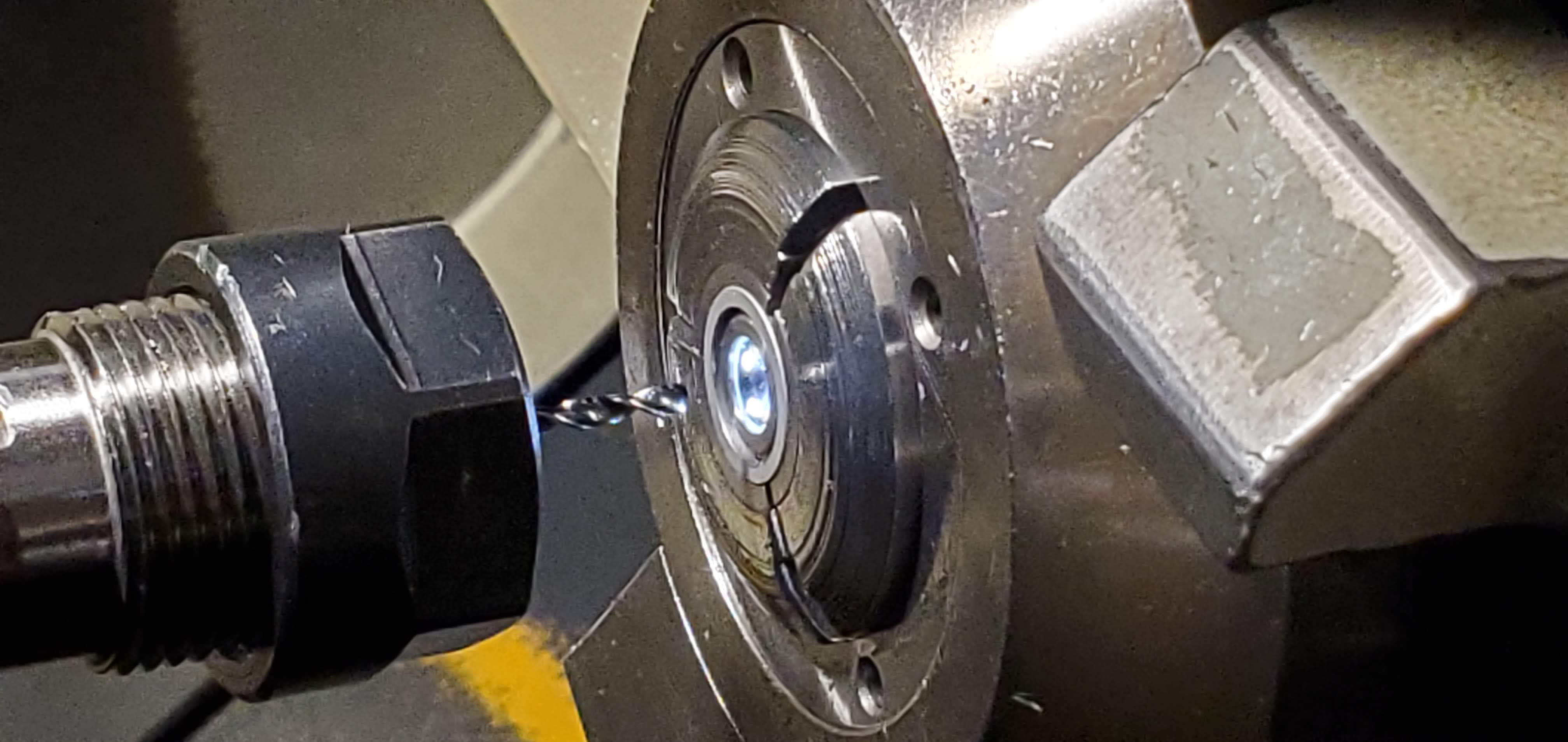

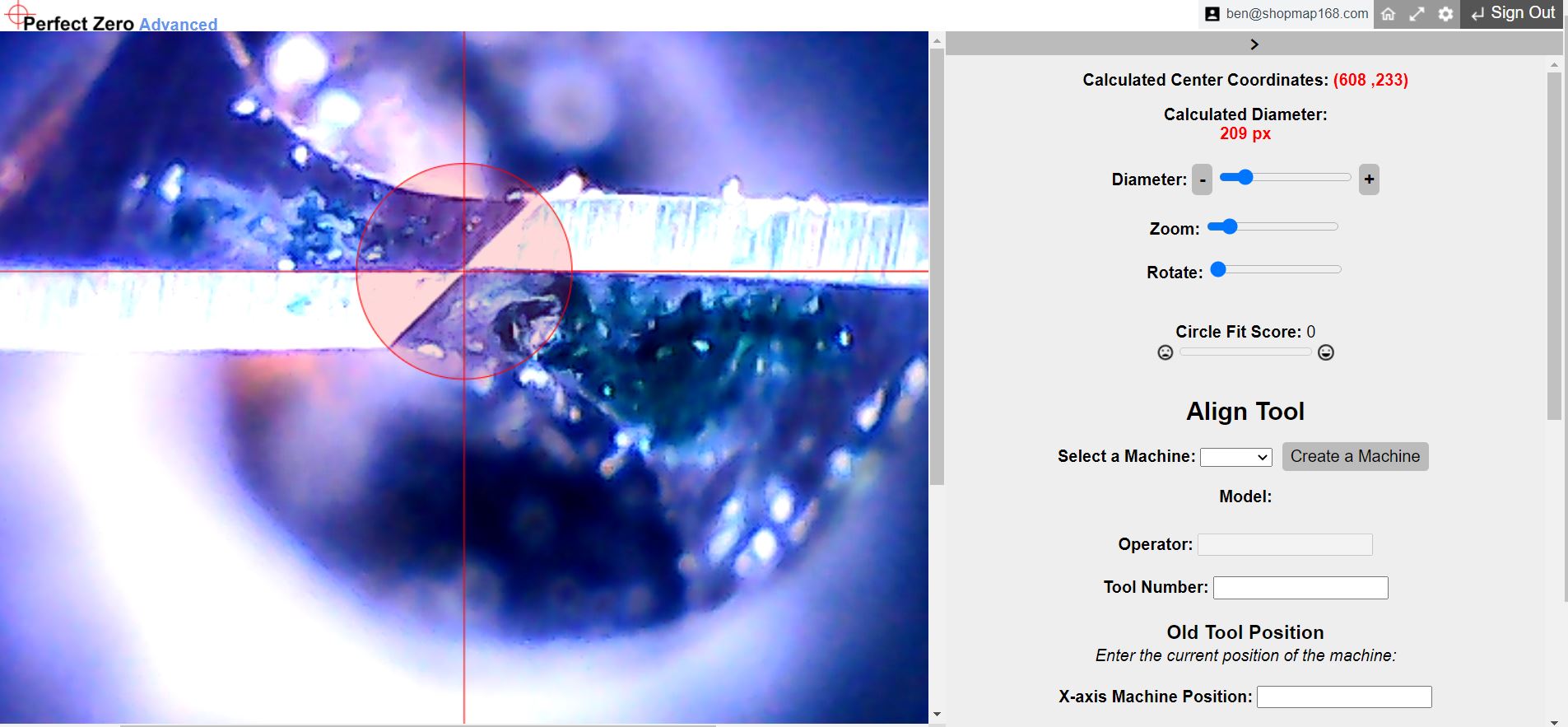

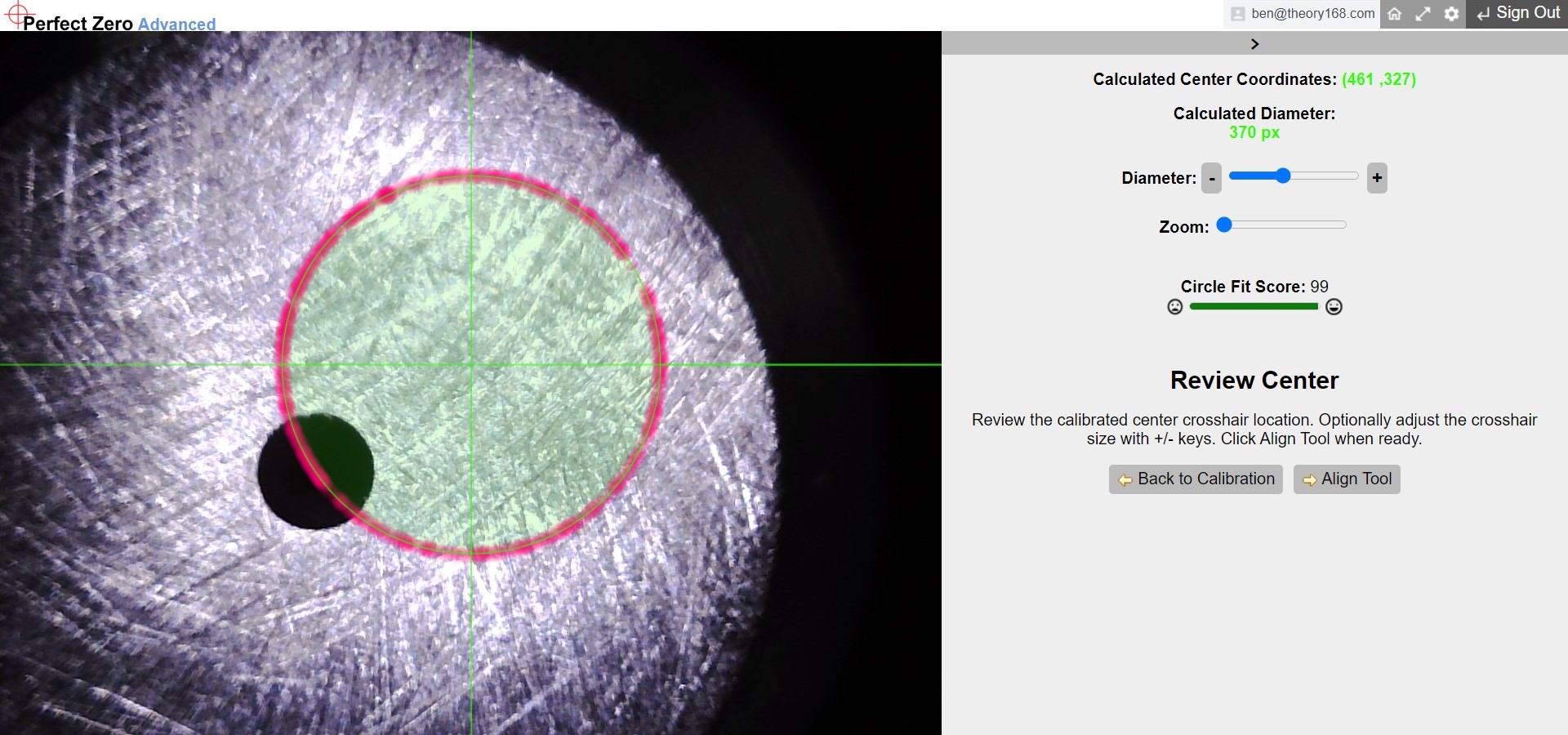

Use an industrial grade camera and state-of-the-art software to perfectly align your tools to the true center of your spindle. No more guesswork, trial and error, busted tools, indicators, probes, lasers, aka fuss.

10 Reasons to Buy Perfect Zero®

- The best method to positionally align tools in all CNC machines

- Easy to use

- Faster setups

- Cost savings because of faster setups and better tool life

- Produce more accurate parts, faster

- Builds confidence of operators and management

- Align tools in the position they will be cutting the material

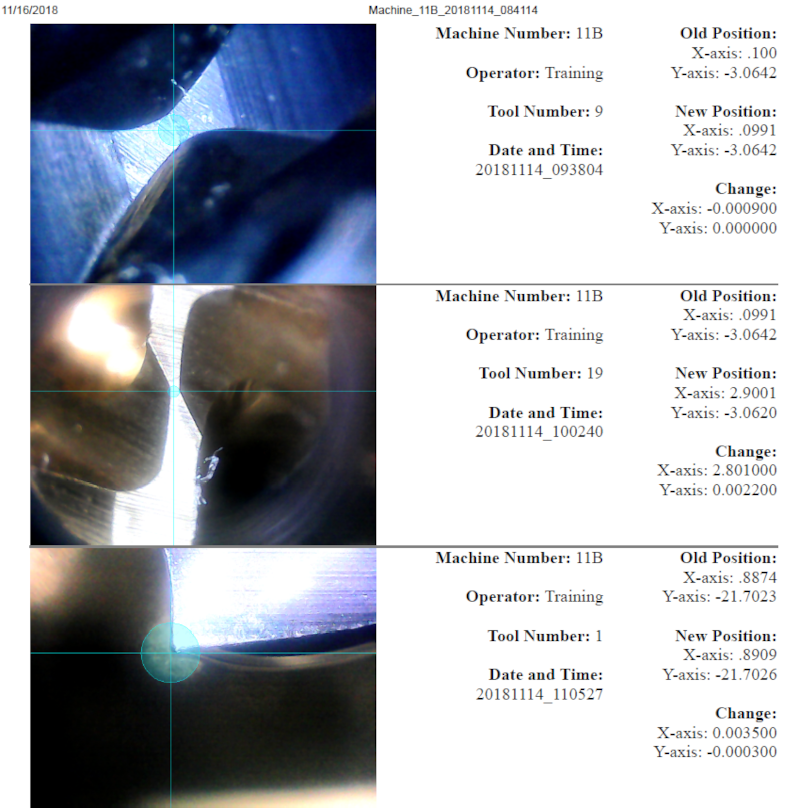

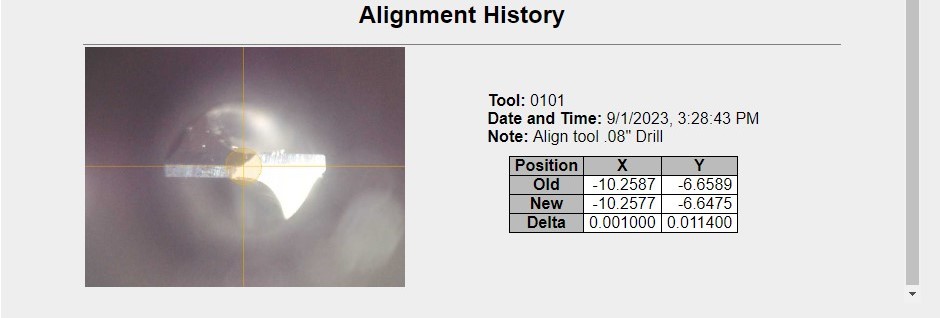

- Record storage for post operation analysis of operator, machine, or tool

- Ideal for saving grid shifts in machine control

- Identify potential tool grind issues using high magnification

It's this easy...

-

Place camera

-

Rotate around target

-

Determine center

-

Jog to tools

-

Align to center

-

Input positions

Save yourself time and headaches with our proven, turn-key solution.

Find your Perfect Zero® CNC Aligment Products

- What are the differences between the Web App and the Locally Installed App?

- What are the computer requirements for the software?

- Can I use the software offline?

- How will I receive the software?

- What comes with the camera?

- Does the camera come with a warranty?

- What is the repair/replacement process for the camera?

- What types of spindles are compatible with the camera?

- What types of machines are compatible with the camera?

- What size of machines are compatible with the camera?

- What types of tools can be aligned?

- What is the field of view and working distance of the camera? Is the zoom or focus adjustable?

- Is the camera waterproof? How is it best cleaned of oil and coolant?

- Is the light adjustable on the camera?

- Do you offer custom cameras?

| Feature | Local | Advanced |

|---|---|---|

| Hardware | Licensed laptops only | Any computer |

| Data Storage | Local | Cloud |

| 1080p HD Video | ✕ | ✓ |

| Seamless Updates | ✕ | ✓ |

| Manual Calibration | ✓ | ✓ |

| Auto Calibration | ✓ | ✓ |

| User Management | ✕ | ✓ |

| Machine Management | ✕ | ✓ |

| Alignment History | ✓ | ✓ |

| Zoom | 150% | 500% |

| Rotation | ✕ | ✓ |

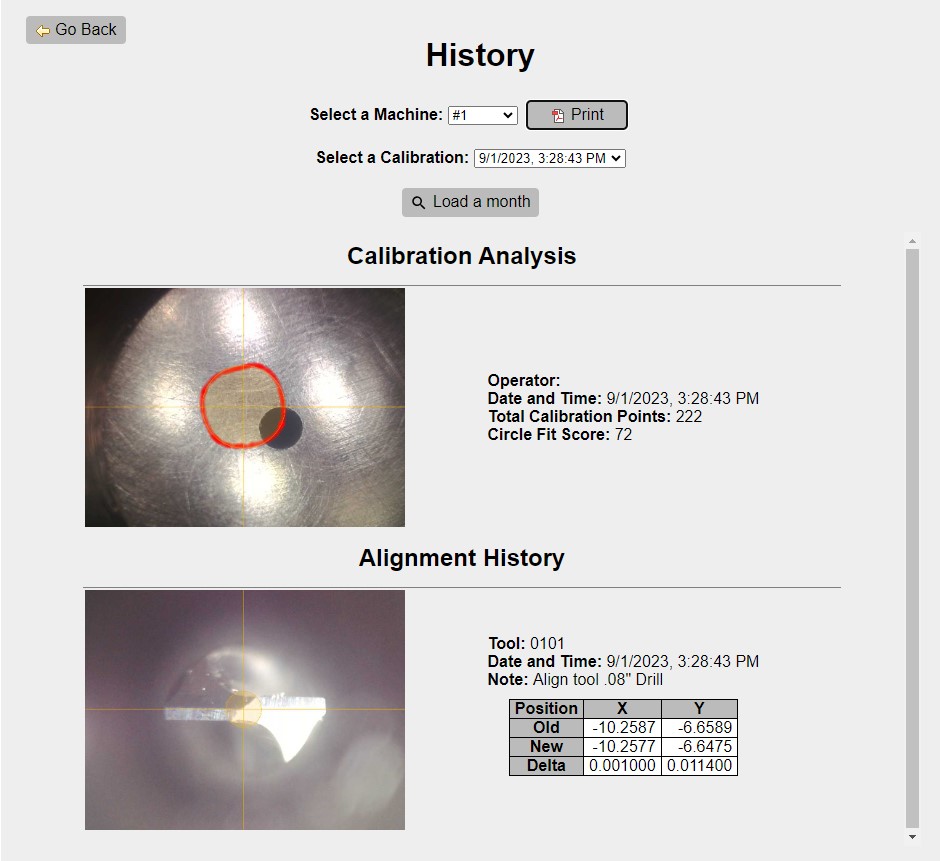

| Circle Fit Score | ✕ | ✓ |

Q: What are the computer requirements for the

software?

A: Depends on which software option you purchase. Our cloud based

web app requires just Google Chrome. Alternatively,

our locally installed, offline-ready app requires Windows 10 or 11, a 64-bit

processor, and a screen resolution of

1366x768 or larger.

Q: Can I use the software offline?

A: Yes! Our locally installed software option does not require an

internet connection during use.

Q: How will I receive the software?

A: We will send you a welcome email that grants you access to our web

app. From there, depending on the option you purchased, you can either download

the local software or immediately begin using CNC-Alignment in your web

browser.

Q: What comes with the camera?

A: Multiple calibration targets, an instruction booklet, and a

hard-sided case.

Q: Does the camera come with a warranty?

A: Yes, a one year manufacturer warranty for any defects with the

camera. This does not cover drops or damage to the camera.

Q: What is the repair/replacement process for the

camera?

A: Contact us about any issues, and we will guide you through returning

the camera to us so we can determine whether we can repair it or if it requires

replacement. We're here to help!

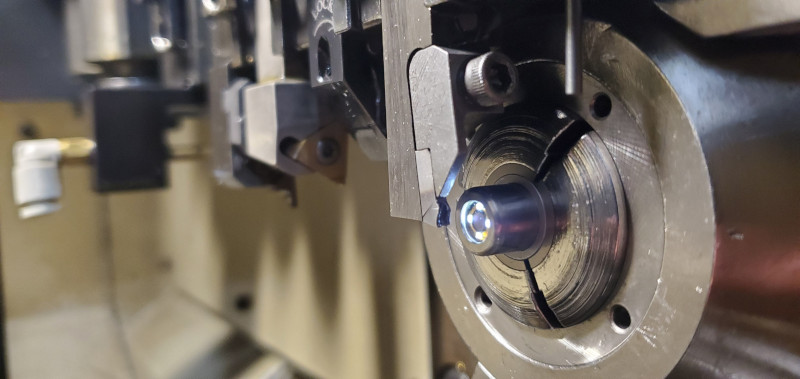

Q: What types of spindles are compatible with the

camera?

A: Main and sub, collet sizes as small as 10mm. We've done custom

orders for even smaller diameters-please contact us if that's of interest.

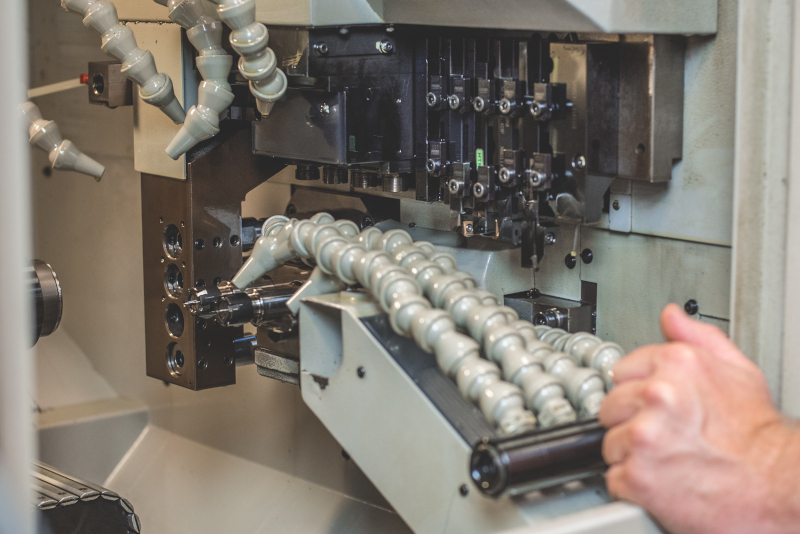

Q: What types of machines are compatible with the

camera?

A: Main spindle cameras are designed for all sizes of swiss machines

down to 4mm bar diameter. Universal cameras fit

swiss, lathes and even mills.

Q: What size of machines are compatible with the camera?

A: Main spindle cameras are designed for all sizes of swiss machines

down to 4mm bar diameter. Universal cameras fit

swiss, lathes and even mills.

Q: What types of tools can be aligned?

A: Symmetrical or asymmetrical, regular or irregular, with any number

of cutting edges. This is the advantage of using a camera rather than lasers or

probes.

Q: What is the field of view and working distance of the camera? Is

the zoom or focus

adjustable?

A: The FOV is about 0.250" and the working distance is 5mm on average

for our cameras. In some of our cameras, the zoom and focus are not adjustable

due to the rigidity

requirements of the calibration process.

Q: Is the camera waterproof? How is it best cleaned of oil and

coolant?

A: The camera is not submersible but it is water resistant and can

withstand the corrosive effects of oil and coolant. To clean your camera, use a

clean rag and light surfactants, finishing with a bit of alcohol and a

microfiber cloth for the camera lens.

Q: Is the light adjustable on the camera?

A: Yes, you can adjust the intensity of the LED light on the camera and

also turn off the light. Ambient light amount is different in every machine, so

you can adjust your lighting to minimize glare while also maximizing edge

definition.

Q: Do you offer custom cameras?

A: Certainly! We leverage our camera expertise to provide you with a

camera that fits your machine and works with our

proprietary software.