Our Innovation Timeline

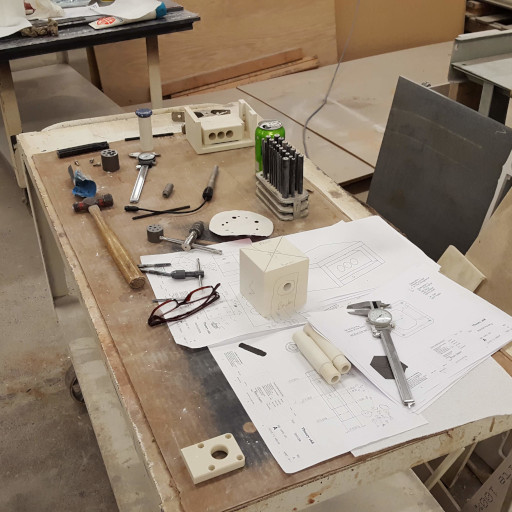

Perfect Zero® Birth

Perfect Zero® was born out of testing dozens of combinations of sensors, lenses, and LEDs; designing a tough, stainless steel housing; and developing companion software to bring it all together. Did we mention coffee?

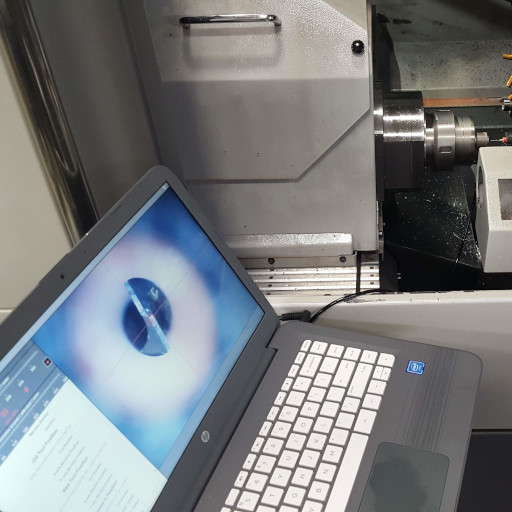

Field Success

The original Perfect Zero® CNC Alignment Camera System performed beyond-expectations in the field. Reports came in of the hardware holding up in the challenging environment in and around machines. We received positive feedback that not only was Perfect Zero® saving time every day, but it was also solving problems that were keeping machines down for weeks.

Multi-Language Support

We released our first major upgrade to the Perfect Zero® CNC Alignment locally installed software. One highlight: we included multi-language support for our global customers.

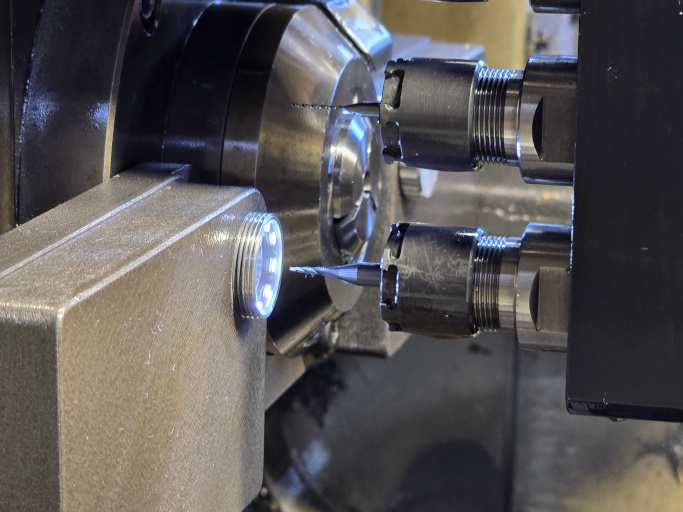

Swiss Camera Innovation

We shrink our cameras to fit Swiss, all the while retaining our proven durability and video quality that has made our CNC Alignment system such a success.

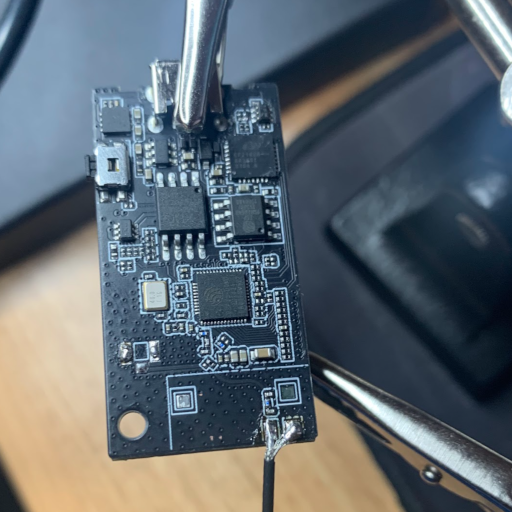

Wireless Development

With hundreds of our corded Perfect Zero® cameras in the field, we begin the long term project of creating a wireless camera for our Perfect Zero® product family. Despite the silicon shortage the world was experiencing, we created a successful wireless prototype and a viable path forward if we could solve one problem: make it small enough.

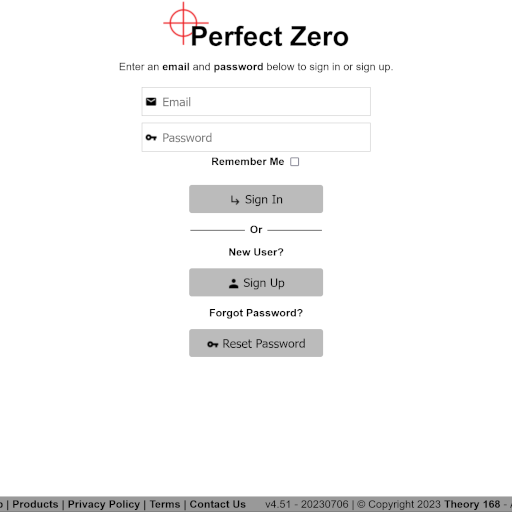

Web Application Launch

We released a web-based software option to compliment the Perfect Zero® camera solutions. With this web-app, we could now seamlessly deliver updates and improvements to our customers, hassle-free. We leveraged the technology and security available to us on the web platform to take a leap forward with video quality, sought-after features, and digital record keeping.

Tool Inspection Solution

We expanded the Perfect Zero® lineup with a tool inspection solution. No more crawling into the machine to see how a tool looks; let our HD endoscope style camera do the trick! We chose the same ruggedness for this camera that our customers have come to expect, and paired it with a new web-based software experience for quickly identifying the tool features you're looking for.

Expanded Solutions

The Perfect Zero® solutions expands to SwissSetter, our tool presetting system for preparing tools outside the machine, Part Inspector, our work-piece inspection system for in-process use and much more, and Shop Vision, our multi camera feed system for never losing sight of your production.

Ultra Innovation

Before 2016, aligning tools on Swiss machines was a time-intensive task, often taking several hours using traditional indicating methods. With Perfect Zero®, we revolutionized the process, enabling you to find the exact tool positions of guide bushing and sub spindle in less than an hour.

Then we introduced Ultra, the next leap forward in tool alignment technology. It has all the benefits of our proven system, and it only takes minutes.

Shop Vision Reborn

We reintroduced Shop Vision with web streaming, monitoring via HDMI, and video recording for historical reference.

.png?alt=media&token=93a43312-ae40-44b5-9d76-78f1d99cb43f)