Ultra Value

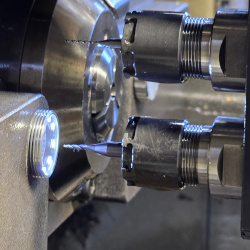

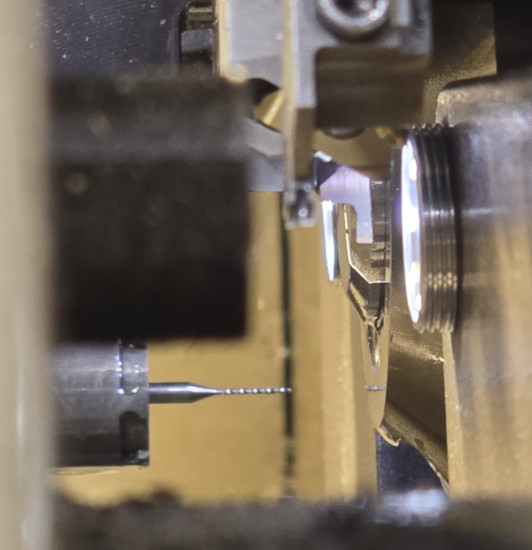

Perfect Zero® Ultra Swiss is a next generation visual tool setting solution — designed to align your Swiss tooling on demand without ever leaving the machine. It offers the same ease of use as our Perfect Zero guide bushing and collet-mounted cameras, but with one key advantage: Ultra Swiss remains installed in your machine at all times, streamlining your workflow and boosting productivity. Simply remove the protective cap, jog your tools in front of the built-in camera, and confirm or adjust positions in just minutes. It has no exterior moving parts to worry about when focusing on your tooling.

How it Works

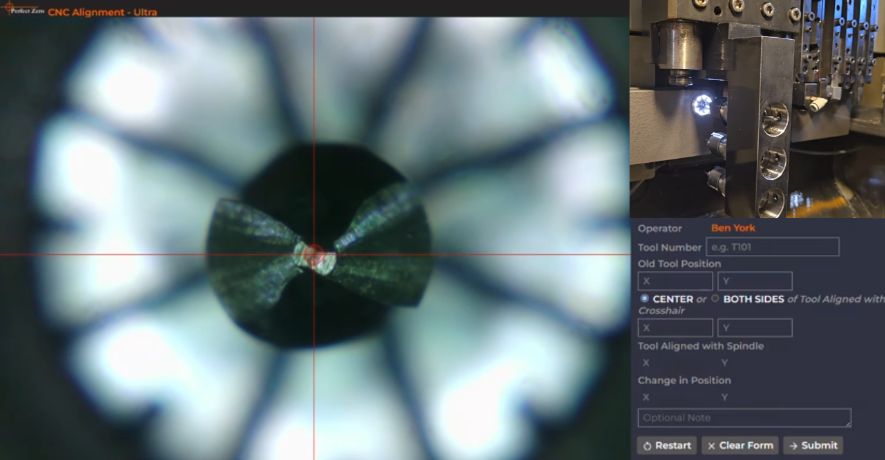

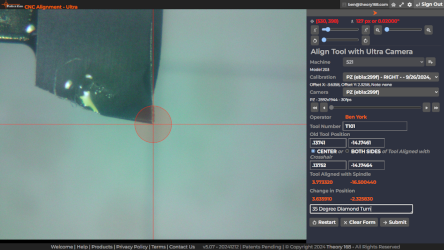

Operators can set tools within minutes — often without stopping production — then quickly resume making parts. The process is simple:

- Blow off any residual oil from the gang slide area

- Unscrew the IP67 high-pressure, oil-proof cap

- Jog a tool in front of the camera to align and set it

- Apply the offset shown in the software to the machine control

It's that quick!

One Time Installation

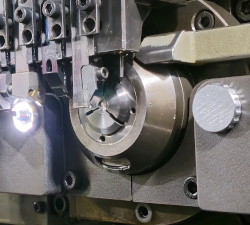

- Mount the Perfect Zero Ultra Swiss to the face of the guide bushing using included hardware

- Align the unit to the gang slide using an indicator

- Connect the cable to the unit and route it to the backside of the machine

- Calibrate Ultra to the center of the guide bushing rotation

That's it. Your Perfect Zero Ultra Swiss is now ready for use.