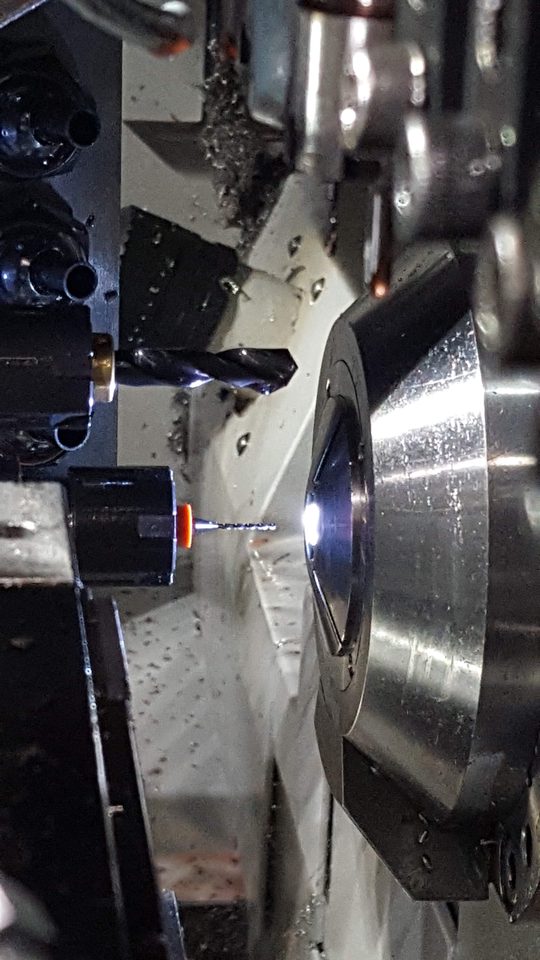

Small hole drilling can be easy!

Here are the steps I like to use for the most successful micro-hole drilling process. It can feel a bit tedious at times to ensure each tool is cutting correctly. These results have been proven many times. This has been a real "art" in the past even for experienced machinists. Perfect Zero® alignment makes the process much easier. It also scales your employees abilities and allows for less experienced operators to make this technical process work.

Swiss and CNC Alignment!

Perfect Zero® is a camera and software system that simplifies tool alignment and gives us abilities that we have never had before. Tool position exactly where the tool is mounted is key. We have cameras to fit even the smallest 4mm swiss machines.

Positionally Align Tools

Tooling must be within 1% for successful hole drilling. As the tool gets smaller it

becomes

even more important. Perfect Zero® gives you the ability to look at the tool mounted in

your

machine exactly where it will cut on your part.

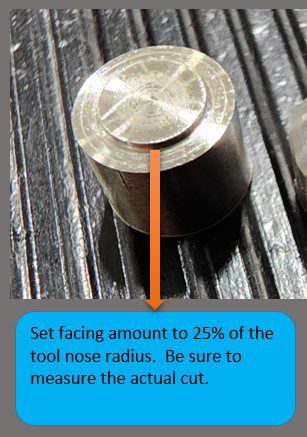

Facing Amount

The amount you face is very critical to making this work. It will also ensure that the

setup

stays capable into production

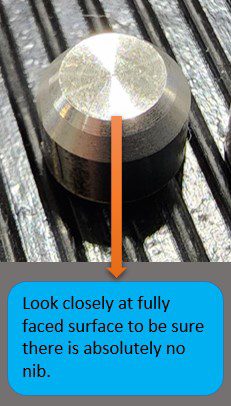

Face Off Quality

Run the face-off in your program. Cut off at least a 1/4" of material and check with

magnification. This must be smooth with as little surface interruption as possible.

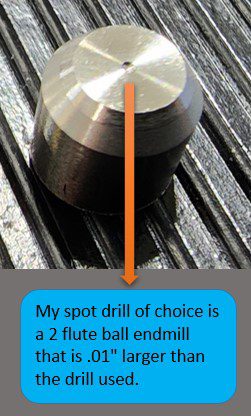

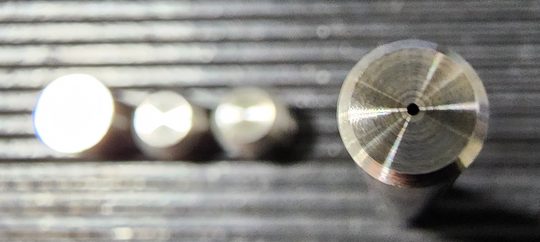

First ID Tool

There are many successful ways to start the ID work. I prefer a pilot drill that is

1.5xD.

These cost a bit more than most tools yet are well worth it. More economical is a ball

end

mill with a very small peck cycle. I generally find in most materials .001 works well.

Too

must will certainly chip the tool out. Different depths of the spot can be applied.

.005-.015" works the best.

First ID Tool

The pilot drill or spot must be exactly on the centerline to work properly. Check and

re-check.

If using a pilot, run only the first .005 depth of cut to check for free machining

indicators such as chatter and material getting pushed around versus sheared. And burs

at

this stage is a sign that you have problems. Most likely misalignment which in turn

means

the tool is not shearing the material.

Longer Tool Life

Ran this process many times and most recently have over 1000 parts in 303 stainless and

still going strong. As the tools start to wear the hole feature will start to drift.

Change

the tools and reset by going through the face-off and check the spot over again. Also,

look

closely at the tooling to see wear trends. Keep in mind tools chipping out may happen

after

the first time it machines the part. If so, there is too much pressure. Back off pecks

and

or feed rates. Typically I like to use .0003" IPR or less for the feed and 25% of the

diameter for the peck.

Start To Drill

Only run each tool .005" deeper than the last tool. Then cut off the part and check

under

magnification. This is the easiest way to be sure there are no issues. If there is any

chatter, tool wobble, or anything that does not look right. Start the process over.